The Future of Cooling Fan Manufacturers in the Age of Sustainable Development

In this blog, we explore why sustainability matters for cooling fan manufacturers, the key challenges they face in adopting greener practices, and the innovative solutions driving the industry toward a more energy-efficient future.

1.Why Sustainability Matters in the Cooling Fan Manufacturers

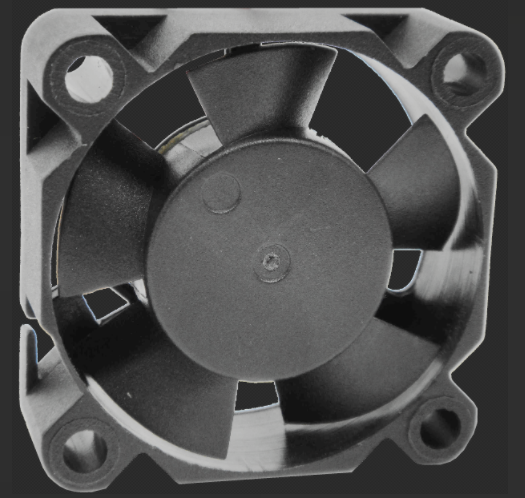

As global industries accelerate their transition toward low-carbon operations, sustainability has become a defining priority for cooling fan manufacturers. Although compact, cooling fans are installed by the millions in systems ranging from EVs and data centers to medical equipment and consumer electronics. Their cumulative environmental impact—across production, usage, and disposal—is significant.

Energy efficiency is at the core of this shift. Today’s customers demand thermal solutions that maintain performance while consuming less power, especially in sectors like renewable energy, industrial automation, and high-performance computing. As energy costs rise and emissions targets tighten, fans must evolve to support smarter, leaner systems.

Additionally, manufacturers must now meet increasingly strict global environmental regulations, such as RoHS and REACH, which restrict hazardous substances and emphasize lifecycle accountability. Compliance is no longer a checkbox—it’s a competitive requirement, influencing procurement decisions across B2B and B2C sectors alike.

Just as importantly, sustainability is now tied to brand reputation and supply chain value. OEMs and global buyers increasingly evaluate vendors through the lens of ESG metrics. Cooling fan manufacturers that invest in clean materials, efficient production, and eco-focused R&D are not only achieving compliance—they’re positioning themselves as strategic partners in building future-ready, responsible technology.

YCCFAN’s dedication to green manufacturing is reflected in its advanced in-house capabilities, including an airflow & pressure test chamber, noise lab, and fully automated production and inspection lines. The company’s quality assurance system meets international benchmarks such as ISO9001, ISO14001, and IATF16949—ensuring each product meets strict energy efficiency, safety, and environmental standards.

As global demand grows for low-carbon, high-efficiency thermal solutions, YCCFAN continues to lead with smart, scalable, and sustainable cooling technologies—partnering with forward-thinking brands in building a cooler, greener future.

Looking for the best partners in energy-efficient cooling? Explore the Top 5 Industrial Cooling Fan Manufacturers for 2025 and see why YCCFAN is trusted worldwide.

https://www.yccfan.com/articledetail/510.html

2.Key Challenges Cooling Fan Factory Face

Transitioning toward sustainability, however, presents complex technical and economic challenges. Cooling fans are precision components, and their design must balance airflow performance, energy efficiency, size, and reliability—all within strict engineering tolerances.

One key challenge is achieving optimal airflow with minimal power draw. High-efficiency fans must move adequate air volumes without sacrificing system stability. To meet these needs, manufacturers are turning to advanced blade designs, refined motor control algorithms, and simulation-driven engineering—yet every refinement must meet cost and scalability demands.

Material selection poses another dilemma. While eco-friendly plastics and recyclable metals align with green goals, they may lack the thermal durability, strength, or cost efficiency required for mission-critical or long-life applications. Finding the right material mix that balances environmental responsibility with long-term performance is a continuous engineering task.

Moreover, cost control remains a major barrier—particularly for smaller cooling fan manufacturers. Sustainable upgrades such as halogen-free compounds, low-emission resins, or automated cleanroom production add upfront investment, which may be hard to absorb in highly competitive markets. Yet, standing still risks losing contracts to suppliers offering more eco-aligned value.

Finally, there’s the growing complexity of global regulatory fragmentation. As more countries introduce their own environmental standards—such as the U.S. Energy Star, China’s YCCFAN, or Korea’s EPEAT—cooling fan makers must adopt flexible, region-specific compliance strategies. This requires traceable material sourcing, modular certifications, and agile documentation systems.

3.Sustainable Innovation: How Cooling Fan Manufacturers Are Evolving

Despite the challenges, the cooling fan factory is embracing innovation to drive measurable environmental progress—without compromising product quality.

A major breakthrough has been the shift to recyclable and low-emission materials, including halogen-free, flame-retardant thermoplastics such as modified PBT and PA6. These materials offer the performance needed for industrial use, while reducing toxic output during production and enabling easier end-of-life recycling.

Another area of rapid development is low-noise, energy-saving fan design. Through enhanced blade geometry, fluid dynamic simulation, and advanced bearings (like FDB or MagLev), manufacturers are delivering quiet fans that maintain airflow at lower RPMs. These improvements not only conserve energy but also meet stricter acoustic standards in hospitals, offices, and smart devices.

Smart fan integration is also changing the game. Modern cooling fans now feature embedded sensors and dynamic control functions such as PWM and I²C protocols. These technologies allow fans to adjust in real-time based on temperature or system load—improving energy efficiency, reducing wear, and enabling predictive maintenance across critical applications.

Lastly, the adoption of brushless DC (BLDC) motor technology has raised the bar for sustainability. Compared to traditional brushed or sleeve-bearing fans, BLDC models deliver higher energy efficiency, longer operating life, lower noise, and finer speed control. With programmable feedback options and reduced EMI (electromagnetic interference), they offer scalable solutions for manufacturers focused on both environmental performance and functional excellence.

Together, these innovations represent more than just a response to regulation—they signal a strategic redefinition of the cooling fan industry. By combining material science, intelligent control, and sustainability-driven design, modern cooling fan manufacturers are playing a vital role in the global shift toward greener, smarter, and more resilient infrastructure.

Learn more:

Want to learn how YCCFAN’s expertise can help you achieve optimal cooling performance? Discover more in Maximizing Performance with YCCFAN: Your Premier Fan Factory.

https://www.yccfan.com/articledetail/499.html

Learn how YCCFAN delivers reliable, high-performance cooling solutions to industries worldwide — YCCFAN: Your Premier Fan Factory for Reliable Cooling Solutions.

https://www.yccfan.com/articledetail/496.html

Conclusion:

The road to sustainability in the cooling fan industry is paved with complex trade-offs, but the direction is clear: innovation, accountability, and efficiency are the new benchmarks of success. Manufacturers that invest in eco-friendly materials, energy-smart designs, and globally compliant production methods are not just keeping pace—they’re leading the evolution.