Do Cooling Fans Use a Lot of Electricity?

When people ask whether a cooling fan uses a lot of electricity, the short answer is usually no—but the real value comes from understanding how little power fans actually need compared with other cooling options. Whether you’re cooling a room, equipment cabinet, or factory space, knowing typical fan power use helps you choose a solution that improves comfort without driving up energy costs.

How Much Electricity Does a Cooling Fan Actually Use?

Typical Power Consumption by Fan Type

Fan Type | Typical Power Use | Real Use Example |

Small DC cooling fan | 5–40 W | Cabinet cooling, electronics thermal management |

Ceiling fan | 15–75 W | Residential and office circulation |

Pedestal / tower fan | 30–100 W | Personal comfort cooling |

Large industrial fan | 80–200 W+ | Factory floor circulation |

Most cooling fans run in the ~20–100 W range. Smaller desk units and compact DC fans are usually closer to the low end, while larger pedestal or industrial models tend to draw more.

Within YCCFAN’s portfolio, DC cooling fan options like DC8038 and DC5015 are built to deliver solid airflow with modest power requirements, so they’re well suited for long, continuous run time without a big electricity penalty. This matches typical real-world use cases where fans are expected to operate steadily around the clock and keep power consumption predictable.

Daily and Seasonal Operating Cost

At most electricity rates, a 50 W cooling fan running nonstop uses around 1.2 kWh per day (50 W×24 h). In real life, that typically comes out to about $0.15–$0.30 per day, depending on your local price per kWh. Even if you run it through the whole summer, the bill is usually only in the“few dollars to low-teens”range, which is exactly why fans are a go-to option for steady, everyday comfort without a noticeable energy hit.

Cooling Fans vs. Air Conditioners

System | Typical Power Use |

Cooling fan | 20–100 W |

Window AC | 1,200–1,800 W |

Central AC | 2,000–3,500+ W |

Cooling fans are significantly more energy-efficient than air conditioners. For example, a typical cooling fan uses just 20–100 watts, while air conditioners can consume 1,200–3,500 watts per hour. This means a fan can run all day for roughly the same cost as an AC unit uses in just a few hours, making fans a smart, cost-effective option for improving comfort without significantly increasing electricity bills.

What Affects How Much Electricity a DC Cooling Fan Uses?

Fan Speed Settings

Fan speed has the biggest impact on power draw—run faster, use more electricity. In day-to-day use, backing off one or two speed steps can often cut energy use by around 30–40%, yet the airflow still feels“good enough”because comfort usually comes from steady movement, not maximum blast.

That’s a key advantage of DC cooling fans. Many YCCFAN DC models support PWM or voltage control, so you can match airflow to real heat demand—ramping up only when temperatures rise and easing off during lighter loads. In practice, this “right-speed” approach is what keeps long-hour operation efficient without sacrificing cooling performance.

Motor Type — AC vs. DC

DC motor cooling fans usually deliver better energy efficiency than AC fans, especially in systems that rarely need“full blast”all day. The advantage shows up most at everyday operating conditions—because most equipment runs at partial load far more often than it runs at peak heat.

In real setups, DC fans often achieve the airflow you actually use with fewer watts, mainly because speed can be matched to demand instead of staying fixed near maximum. PWM or voltage control also makes the airflow easier to“trim,”so you avoid pushing extra air that doesn’t improve cooling but still costs power. And when a fan can hold steady at lower RPM, the sound tends to be less intrusive in offices, equipment rooms, and other close-by environments.

This is one reason DC fans are common in long-runtime applications. YCCFAN’s DC cooling fan lineup is built around the same idea: efficient airflow with controllable speed, so systems can run continuously with predictable performance and less wasted electricity.

Cooling Fan Size & Application

Power use isn’t only about the cooling fan—it’s about whether the fan is actually matched to the airflow job. A right-sized fan that delivers useful airflow to the hot zone often costs less to run than adding multiple small fans that mostly stir air where it doesn’t help.

1.Match airflow“style”to the task

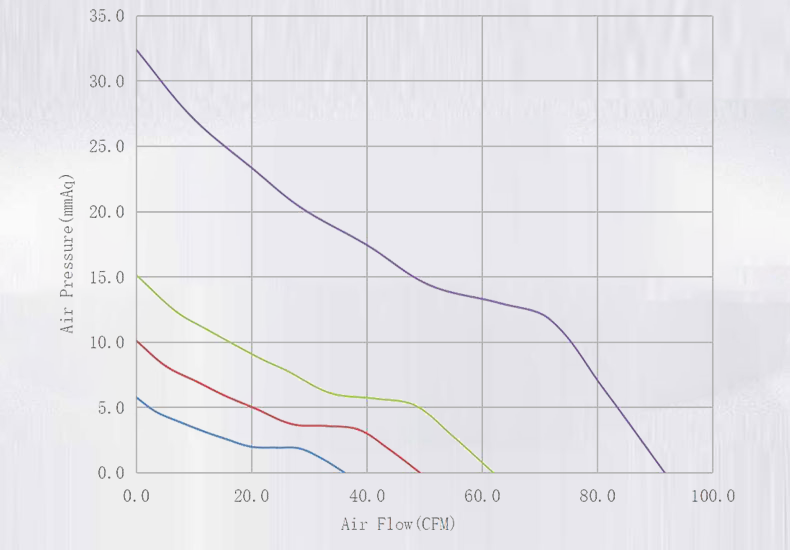

If air has to push through filters, grilles, tight enclosures, or short duct sections, the dc fan needs enough pressure capability to keep flow from collapsing once installed. That’s why engineers don’t look at airflow alone—they check the airflow–pressure curve together. For example, YCCFAN publishes both airflow and static-pressure specs for models like DC8038, which helps estimate how the fan will behave in a real, restrictive path—not just in free air.

2.Resistance quietly drives up watts

As filters load or vents get partially blocked, the system becomes harder to breathe. In the field, this usually shows up as “same noise, less cooling” at first—then higher speed/current and more audible turbulence. Keeping the airflow path clean can save electricity as effectively as upsizing the fan, because the fan doesn’t need to work as hard to move the same amount of air.

3.Placement beats brute force

A smaller cooling fan aimed at the hotspot—plus a clear inlet-to-exhaust route—often outperforms a larger unit sitting in a recirculation loop. In practical layouts, small changes like redirecting airflow across a heat sink or opening a return path can let you step down fan speed and still hit the same temperature target.

4.Avoid oversizing for CFM alone

Extra CFM you can’t“use”tends to turn into turbulence, noise, and wasted power. If the enclosure can’t pass that much air, a higher free-air number won’t translate into better cooling—just more fan work.

5.Best approach: size for real conditions, then tune

Choose a fan that meets airflow needs under expected resistance, then fine-tune speed. With DC fans that support PWM/voltage control—common across YCCFAN’s DC cooling fan range—you can run “as fast as needed” instead of “as fast as possible,” which is usually the simplest way to keep long runtimes efficient and predictable.

Conclusion

In real-world use, cooling fans are one of the most energy-efficient ways to manage heat. Most models run on just a fraction of the power required by air conditioning, especially when speed control and proper sizing are used. By choosing the right fan type, matching it to real airflow resistance, and tuning speed instead of running at full output, users can achieve steady cooling with predictable, low electricity use. That’s why DC cooling fans—such as those in YCCFAN’s range—are widely used in long-runtime applications where efficiency matters as much as airflow.

Read more:

FAQ

1.Does a cooling fan use a lot of electricity?

No—most cooling fan models use relatively low wattage, so daily running cost is usually small.

2.How many watts does a typical cooling fan use?

Commonly around 20–100W, depending on size, speed, and application.

3.Is it cheaper to run a cooling fan or an air conditioner?

A cooling fan is far cheaper to run; AC units draw much higher power for the same hours.

4.Do DC cooling fan models save more energy than AC fans?

Yes—DC cooling fan designs are typically more efficient, especially at partial speed.

5.How can I lower a cooling fan’s electricity cost?

Use a lower speed, keep airflow paths clean, and choose the right fan size for the job.