How Cooling Fan Selection Improves Equipment Performance and Longevity

This guide explores the importance of cooling fans, how proper selection can enhance efficiency and reliability, and the role of YCCFAN’s advanced solutions in ensuring the long-term performance of your systems.

What is a Cooling Fan?

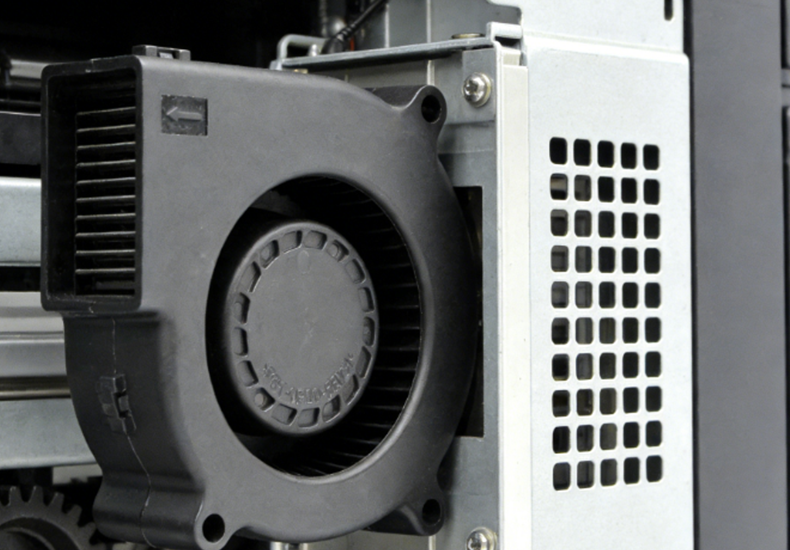

A cooling fan helps lower the internal temperature of equipment by directing airflow towards heat-producing components like heat sinks. It works through active convection, where the fan circulates air to remove heat, keeping the equipment within its ideal temperature range. Cooling fans are commonly used in devices such as computers, servers, cars, and air conditioners. They are especially important during heavy use, as they prevent overheating, ensuring the equipment runs smoothly and lasts longer.

Why the Performance and Lifespan of Industrial Cooling Fans Matter

Cooling fans are essential in electronic devices, playing a key role in dissipating heat and maintaining an ideal operating temperature to prevent overheating. However, the performance and longevity of the fan itself directly impact the stability and reliability of the equipment. When the fan's performance declines or it reaches the end of its useful life, it can lead to a variety of issues that disrupt the normal operation of the device.

1.The Importance of Consistent Heat Dissipation

The main job of a industrial cooling fan is to move air across the heat-producing components and carry the excess heat away from the device. If the fan begins to underperform—due to factors like reduced speed or damaged blades—it will struggle to disperse heat effectively. As a result, the device may overheat, affecting its efficiency, stability, and potentially causing permanent hardware damage.

2.Performance Decline from Industrial Fan Malfunctions

As cooling fans age, their performance can degrade. This may involve slower speeds, worn-out bearings, or even total failure. When this occurs, the device may no longer stay within its optimal temperature range, leading to throttling of critical components such as the CPU or GPU, which results in decreased performance. Overheating can also trigger system shutdowns or crashes, interrupting productivity and causing downtime.

3.Minimizing Maintenance Costs and Downtime

The lifespan of a industrial cooling fan has a direct effect on maintenance needs. Frequent fan failures can lead to more regular repairs and part replacements, which increases maintenance costs and results in system downtime. Choosing a durable, high-quality fan reduces these risks, improving the overall reliability of the equipment while keeping maintenance expenses low.

4.Protecting Other Components' Lifespan

When a cooling fan underperforms, it leads to higher temperatures, which are a major cause of wear and tear on electronic components. Prolonged exposure to excessive heat can accelerate the degradation of sensitive parts like capacitors, semiconductors, and circuit boards. A well-functioning cooling fan helps prevent this, preserving the health of the entire system and extending its overall lifespan.

5.Boosting Energy Efficiency and Reducing Consumption

In high-demand systems, such as data centers or renewable energy setups, the performance of the cooling fan directly influences both energy consumption and overall system efficiency. If the fan's performance is compromised, heat dissipation becomes less effective, requiring more power to maintain operations.A blower fan that operates efficiently helps optimize energy use, improving system performance while reducing energy costs.

6.Ensuring Environmental Durability and Reliability

In harsh or challenging environments, the right cooling fan is even more important. For instance, fans in industrial equipment or vehicles must be resistant to dust, moisture, and extreme temperatures. If a fan’s lifespan is too short, contaminants can infiltrate the device, raising the risk of failure.Choosing a blower fan with the right environmental protection ensures long-lasting, reliable performance under difficult conditions.

How Proper Blower Cooling Fan Selection Improves Performance

1.Active Heat Dissipation

Cooling fans work by using forced convection to move air across heat-generating components like heat sinks, efficiently carrying away excess heat. This active cooling prevents temperatures from reaching critical levels, avoiding performance throttling or unexpected shutdowns.

2.Maintaining Optimal Operating Conditions

Keeping equipment within the ideal temperature range is essential for optimal performance. By choosing the right blower fan, you ensure that components like CPUs and GPUs stay cool, operate efficiently, and maintain stable performance without the risk of overheating.

3.Enhanced System Efficiency

Proper fan selection not only improves cooling but also boosts overall energy efficiency, especially in high-performance environments like data centers or renewable energy systems. By effectively managing heat, the fan helps optimize system performance and minimize energy consumption.

How Proper Industrial Blower Fan Selection Extends Longevity

1.Prevents Component Degradation

Excessive heat is a major factor in the premature wear of sensitive components like capacitors, semiconductors, and circuit boards. By selecting the right cooling fan, thermal stress is minimized, helping to prevent overheating and extend the life of these critical parts.

2.Reduces Maintenance Costs and Downtime

Proper fan selection helps avoid heat-related failures, reducing the need for frequent repairs and minimizing system downtime. This improves the overall reliability of the system and results in significant savings on maintenance costs.

3.Protects from Environmental Damage

Choosing fans with the appropriate environmental ratings, such as dust or moisture resistance, ensures durability in harsh conditions. Fans designed for tough environments protect the equipment, ensuring its long-term reliability and performance.

How YCCFAN Cooling Solutions Enhance Equipment Longevity and Reliability

Prevents Component Degradation

Excessive heat is one of the primary causes of wear and tear on sensitive components like capacitors, semiconductors, and circuit boards.YCCFAN's cooling solutions are specifically designed to reduce thermal stress and provide optimal heat dissipation. By choosing the right fan, you help prevent overheating, which in turn extends the lifespan of these critical components. Our DC Blower Fans, crafted from durable materials and precision-engineered for high performance, effectively manage temperature, safeguarding your equipment from the harmful effects of excessive heat.

Reduces Maintenance Costs and Downtime

Selecting the right industrial blower fan plays a crucial role in minimizing heat-related failures.YCCFAN’s fans, equipped with advanced features such as motor protection, PWM control, and integrated sensors, ensure long-term, efficient operation.This reduces the need for frequent repairs and cuts down on downtime, improving system reliability.With lifespans up to 70,000 hours depending on the bearing type,YCCFAN fans offer a low-maintenance, cost-effective solution that keeps your operations running smoothly.

Protects from Environmental Damage

Durability is key, especially in harsh environments.YCCFAN fans are designed with robust materials and environmental protection features,including resistance to dust and moisture. Whether in industrial applications or high-performance office equipment, our fans ensure reliable performance even in challenging conditions, helping to preserve the longevity and functionality of your systems over time.

Read more:

https://www.yccfan.com/articledetail/what-are-the-different-types-of-cooling-fans.html

https://www.yccfan.com/articledetail/how-to-choose-an-industrial-cooling-fan.html

Conclusion

Proper cooling fan selection is a key factor in maximizing the efficiency, performance, and longevity of electronic systems. Whether it's preventing overheating, reducing maintenance costs, or ensuring reliability in harsh environments, the right cooling solution is indispensable.