How to Choose the Right 80mm Fan: A Complete Buying Guide

Among the many available options, the 80mm fan stands out as a versatile choice used in everything from desktop PCs to industrial control panels. But how do you determine which 80mm fan is the best fit for your application? In this guide, we’ll walk you through the key considerations for choosing the right 80mm fan, including application-specific needs, bearing types, airflow dynamics, and noise levels.

1.Understanding 80mm Fan Applications

The 80mm fan is one of the most versatile and widely used cooling solutions in compact electronics. It offers a practical balance between airflow performance and space efficiency, making it ideal for systems where size constraints are a concern, but reliable cooling is still essential.

In desktop PCs, 80mm fans are often found in rear exhaust positions or mounted on CPU coolers in mid-sized cases. They deliver enough airflow to regulate internal temperatures effectively, without creating excess noise or occupying too much space.

In power supplies, especially older ATX units and compact industrial models, these fans help remove heat from densely packed components like transformers and voltage regulators. Their form factor allows them to fit where larger fans can’t, while still maintaining consistent airflow.

In networking and communication equipment—such as routers, switches, and amplifiers—80mm fans are favored for their steady, directional airflow and compact design. They ensure critical circuit boards stay cool during continuous operation in tight enclosures.

You’ll also find them in 3D printers, embedded systems, and audio amplifiers, where quiet operation and low power consumption are just as important as cooling. In these applications, the 80mm micro fan stands out not only for its size, but also for its silent, efficient performance.

Overall, what makes the 80mm mini fan so popular is its ability to deliver targeted, reliable cooling without taking up unnecessary space—a valuable trait in both consumer and industrial electronics.

Learn more:

Exploring the Role of 80mm Fans in Power, Control, and Computing Devices (yccfan.com)

2.Micro Fan Bearing Types: Which One Is Right for You?

Bearing Type | Noise Level | Lifespan | Mounting Orientation | Cost | Best For |

Sleeve Bearing | Low (initially) | Short (~30,000 hrs) | Horizontal preferred | Low | Home use, light-duty devices |

Ball Bearing | Moderate | Long (~60,000 hrs) | Any orientation | Medium | Industrial, 24/7 systems |

FDB / Hydraulic | Very low | Very long (~100,000 hrs) | Any orientation | High | Quiet offices, high-end electronics |

Learn more:

When selecting an 80mm fan, the bearing type plays a key role in determining how quiet the fan runs, how long it lasts, and where it’s best installed. Here’s a breakdown of the three most common types and what each is best suited for:

2.1 Sleeve Bearing

Sleeve bearings are a cost-effective choice, often used in entry-level fans. They’re relatively quiet at first but tend to wear out more quickly—especially in warmer or more demanding environments. Since they rely on gravity for lubrication, they perform best when mounted horizontally. For light-duty applications like home electronics or occasional-use devices, they’re a practical and affordable option.

2.2 Ball Bearing

Ball bearings are built for longevity and reliability. They handle higher temperatures well and can be mounted in any orientation without impacting performance. This makes them ideal for systems that run continuously, such as network equipment or industrial devices. Although they’re slightly noisier and more expensive than sleeve bearings, the added durability makes them a smart investment for long-term use.

2.3 Fluid Dynamic Bearing (FDB)

FDB, also known as hydraulic bearings, offer the best of both worlds—quiet operation and extended lifespan. They use a thin film of fluid to reduce friction and vibration, which helps keep noise levels low over time. These bearings are perfect for premium PCs, home theaters, and other setups where silent, stable performance is a top priority.

3.Airflow vs. Static Pressure: What Miniature Fan Really Matters

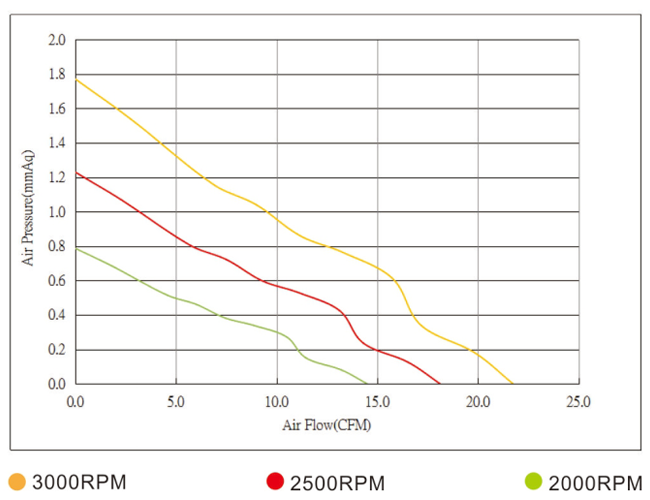

Choosing the right 80mm fan isn’t just about size—it’s about how effectively it moves air in your specific setup. Two key performance metrics define that: airflow and static pressure.

Airflow (measured in CFM) refers to the volume of air a fan can move in open space. Fans with high airflow are ideal for unobstructed environments, such as open cases or areas without filters or tight grills.

Static pressure, in contrast, indicates how well a fan can push air through resistance, such as heatsinks, dust filters, or narrow vents. If your system has airflow restrictions, fans designed for static pressure will perform far better.

In reality, many setups—especially compact builds—have a mix of open and blocked paths. That’s why modern 80mm fans often aim for a balance, providing both decent airflow and enough pressure to handle real-world challenges.

4.Mini Fan Noise Level Considerations

In systems where quiet operation is important—such as home offices, bedrooms, or media centers—fan noise can be just as critical as cooling power. A high-performing fan that’s too loud can quickly become distracting. Understanding what affects miniature fan noise and how to evaluate it can help you choose an 80mm fan that keeps both temperature and noise under control.

4.1 Understanding Noise Ratings (dB)

Fan noise is measured in decibels (dB), and most 80mm fans range between 18 to 35 dB, depending on speed, bearing type, and blade design. Here's how to interpret those numbers:

Below 20 dB: Virtually silent—suitable for quiet workspaces or entertainment systems.

20–30 dB: Noticeable in a silent room but acceptable for most everyday environments.

Above 30 dB: Clearly audible, common in industrial or performance-focused builds.

Keep in mind that noise perception is subjective. A 25 dB fan might seem quiet in a living room but intrusive in a silent bedroom. Always consider your actual environment when evaluating specs.

4.2 What Affects Fan Noise?

Fan noise comes from more than just how fast the blades spin. Here are the key contributors:

Bearing Type: Fans with fluid dynamic (FDB) or hydraulic bearings tend to operate more quietly and stay smooth over time. Ball bearings are louder but more durable in high-load conditions.

Fan Speed (RPM): Higher RPM equals more airflow—but also more noise. PWM (pulse-width modulation) allows fans to adjust speed dynamically based on temperature, reducing noise during low demand.

Blade Design: Blade shape, angle, and spacing all impact turbulence and airflow efficiency. Some fans are optimized to minimize whine and vibration without reducing performance.

4.3 Choosing a Quiet Fan (Without Compromising Performance)

If silence is a priority but you still need effective cooling, consider these tips:

Opt for PWM-enabled fans, so the speed automatically adjusts with system load.

Avoid fixed-speed fans running at high RPM, unless noise is not a concern.

Look for noise-optimized designs with anti-vibration features and acoustically tuned blades.

Check real-world reviews or acoustic test data, since dB ratings on spec sheets don’t always reflect actual user experience.

For quiet environments, aim for fans rated below 25 dB, and prioritize those with fluid bearings and PWM control. If you’re building for performance, a slightly higher noise level may be acceptable—but a well-chosen fan can still keep the system cool without overwhelming your ears. With the right design and features, cooling efficiency and quiet operation can absolutely coexist.

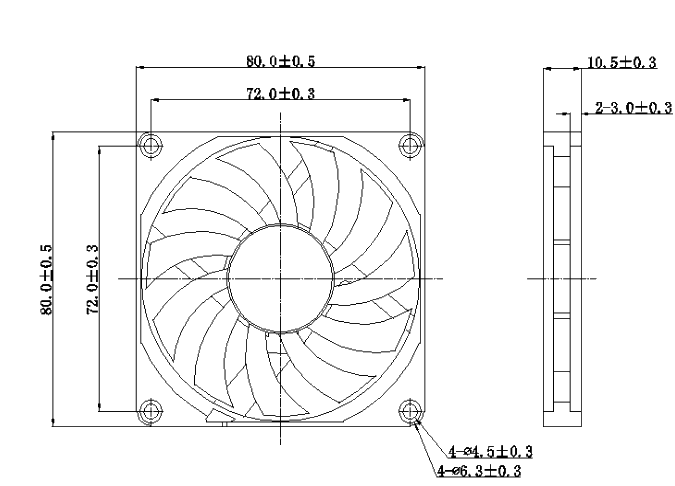

5.YCC FAN DC 8010 – High-Speed, Low-Noise Compact Cooling Fan

The YCC FAN DC 8010 is a high-performance, compact DC micro cooling fan known for its fast rotation speed and excellent noise control. Operating at approximately 30 dB, it’s an ideal solution for cooling in tight or space-constrained environments.

As a trusted brand in the cooling industry, YCC FAN offers full ODM/OEM customization services. No matter what size or specification you need, simply provide your desired dimensions, and YCC FAN will deliver a tailored cooling solution to match.

Learn more:

If you're still unsure about which brand to choose, stop hesitating—go with YCC FAN, the name professionals rely on for quiet, efficient, and customizable cooling fans.

Learn more:

Top 5 Industrial Cooling Fan Manufacturers in 2025 (yccfan.com)

The Science Behind Cooling Fans: How They Keep Your Devices Cool (yccfan.com)

Centrifugal Fan vs. Axial Fan (Part 1): Working Principles and Best Use Cases in 2025 (yccfan.com)

Conclusion

Choosing the right 80mm fan isn't just about meeting cooling requirements—it’s about optimizing system performance, reliability, and user experience. By understanding your specific application, comparing bearing technologies, evaluating airflow versus static pressure, and considering acoustic performance, you can confidently select a fan that delivers long-term value and stability.