80mm Fans vs 120mm Fans: Which Fan Size is Better?

Smaller 80mm fans, sometimes called micro or miniature fans, fit seamlessly into tight spaces but operate at higher speeds. Larger 120mm fans provide stronger airflow with quieter operation, suitable for more spacious setups. But which size truly meets your cooling requirements? This guide explores the key differences between 80mm and 120mm fans to help you make the best choice.

Learn more:

How to Choose the Right 80mm Fan: A Complete Buying Guide (yccfan.com)

1.Understanding Fan Size: 80mmvs 120mm

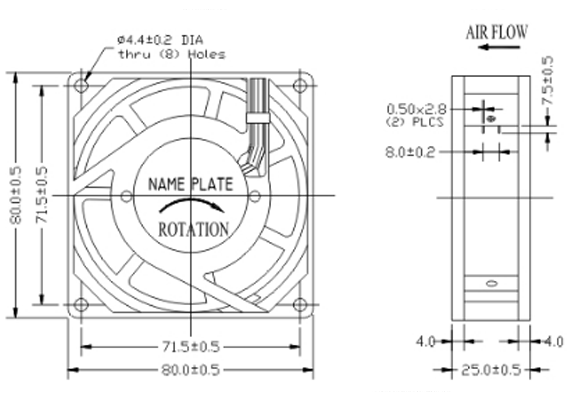

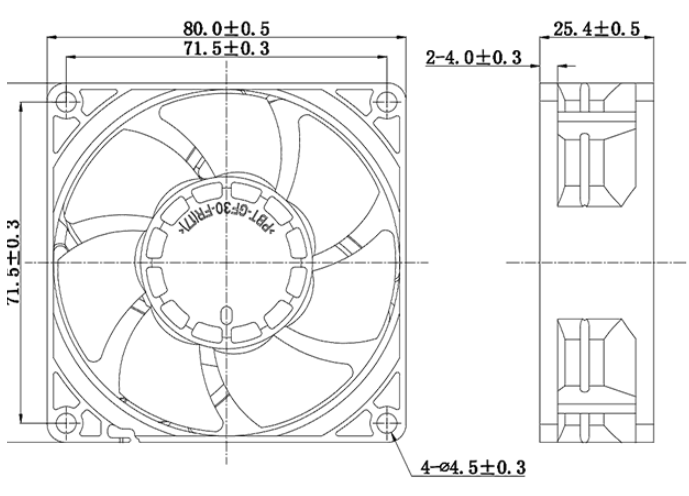

When choosing between an 80mm fan and a 120mm fan, understanding their physical differences and typical uses is crucial. An 80mm fan, measuring 80mm × 80mm × 25mm, is typically found in compact electronics such as small computer cases, power supply units, and industrial equipment with limited space. In contrast, a 120mm fan (120mm × 120mm × 25mm) is commonly used in larger computer chassis, servers, and advanced cooling setups, where there's ample room for installation.

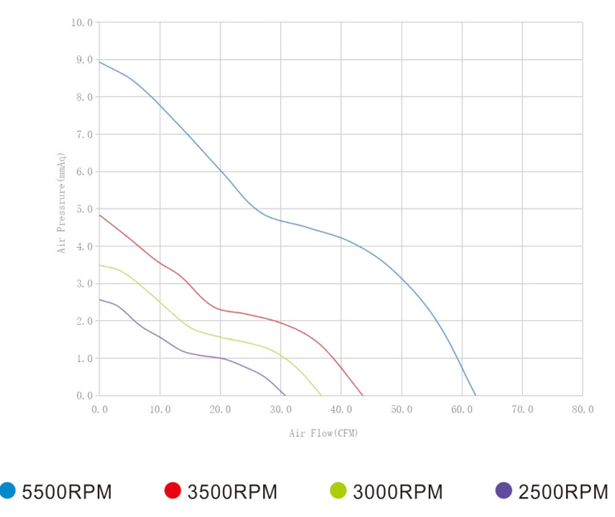

The size directly influences cooling performance because larger fans usually move more air (higher CFM) at lower rotational speeds (RPM). As a result, 120mm fans often produce less noise while providing more efficient cooling. Conversely, 80mm fans, though space-saving, typically run at higher speeds, generating higher noise levels and slightly less airflow efficiency. Therefore, fan size selection significantly impacts cooling efficiency, noise level, and overall system compatibility.

2.80mm fans vs 120mm Fans – Key Differences at a Glance

Comparison Factors | 80mm Fan | 120mm Fan |

Airflow (CFM) | Moderate | High |

Static Pressure | Typically Higher | Moderate (but varies) |

Noise Level (dBA) | Higher (due to high RPM) | Lower (due to lower RPM) |

RPM (Fan Speed) | High | Lower |

Energy Consumption | Lower per fan | Slightly higher per fan |

Efficiency | Less efficient airflow/noise ratio | More efficient airflow/noise ratio |

Space Requirements | Ideal for compact spaces | Needs larger installation space |

Mounting Compatibility | Suitable for tight installations | Best for spacious chassis |

Typical Applications | Small electronics, power supplies, compact industrial equipment | Large PC cases, servers, advanced cooling setups |

Cost | Generally cheaper | Slightly more expensive |

Lifespan & Reliability | Shorter lifespan (due to higher RPM & wear) | Longer lifespan (slower RPM reduces wear) |

Learn more:

3.A comparison between 80mm fans and 120mm fans

3.1 Airflow and Cooling Performance

Airflow performance, measured in CFM (Cubic Feet per Minute), differs notably between micro fan sizes.Usually, a 120mm fan pushes more air at lower rotational speeds (RPM), delivering effective cooling quietly. Conversely, an 80mm fan often generates higher static pressure, making it ideal for compact systems or those with restricted airflow paths. Thus, if your cooling scenario involves densely packed components or narrow ventilation, an 80mm micro fan might be preferable. For larger, more open spaces requiring generous airflow, a 120mm fan generally offers superior cooling effectiveness.

3.2 Noise Levels: Is Bigger Quieter?

Fan size has a direct impact on noise levels. Larger 120mm fans operate at lower RPM while still providing sufficient airflow, which significantly reduces operational noise. 80mm mini miniature fans, however, spin faster to compensate for their limited size, resulting in increased noise. Practically, if minimizing noise is crucial for your application, a larger fan is typically the better choice. Still, the optimal decision should balance your noise tolerance against required cooling performance.

3.3 Power Consumption and Efficiency

80mm miniature fans generally consume slightly less power per unit because of their smaller motors and blades. However, although 120mm fans may consume marginally more energy, they offer better overall airflow efficiency—delivering more cooling per watt. Especially in continuous or high-performance applications, larger fans frequently prove more energy-efficient over the long term. Therefore, while an 80mm fan initially appears economical, a 120mm fan often provides better overall efficiency and cost-effectiveness in extended use.

3.4 Space and Installation Considerations

Available installation space often dictates fan size selection. 80mm fans suit compact environments, such as small PCs, densely populated control units, and tight industrial equipment. Meanwhile, 120mm fans require more space but offer greater mounting flexibility, quieter operation, and improved airflow direction. Ultimately, evaluate your space constraints carefully: compact setups benefit from 80mm fans, whereas systems with ample room typically perform better with 120mm fans.

3.5 Cost and Value for Money

When considering costs, 80mm fans typically have a lower initial price due to simpler construction. However, their higher rotational speeds can increase wear, shortening lifespan and potentially raising replacement costs over time. In contrast, 120mm fans, although slightly more expensive initially, usually offer better long-term durability due to lower RPM and reduced wear. For installations prioritizing long-term reliability and overall value, larger fans often represent the wiser investment.

4.Making the Right Choice: 80mm or 120mm?

Choosing between an 80mm and a 120mm fan ultimately depends on your specific application. Here’s a simplified checklist highlighting key considerations for common scenarios:

4.1 PC Cases:

If you're dealing with a compact case or have limited mounting space, an 80mm fan is typically the better choice due to its smaller footprint and ability to produce higher static pressure. On the other hand, if your system has sufficient space and you prioritize quieter operation with better airflow, a 120mm fan will generally provide superior cooling performance.

4.2 Servers and Networking Equipment:

For server and networking environments, continuous and efficient cooling is essential. In standard or rack-mounted setups with sufficient space, a 120mm fan is usually recommended for its lower noise and reliable cooling. However, in tighter or specialized installations where space is at a premium, opting for an 80mm mini fan might become necessary despite slightly increased noise.

4.3 Industrial Equipment:

Industrial applications often require a balance of durability, airflow, and space efficiency. If your equipment is densely arranged or has restricted airflow pathways, selecting an 80mm mini fan can be advantageous due to its higher static pressure capability and compact size. Conversely, in larger cabinets or equipment that demands consistent cooling at lower noise levels, a 120mm fan typically delivers better long-term reliability and performance.

Below is a clear summary table highlighting the key considerations:

Application | Recommended Fan Size | Key Factors |

Small or Compact PCs | 80mm | Space constraints, higher static pressure |

Standard or Gaming PCs | 120mm | Quiet operation, higher airflow efficiency |

Servers & Network Devices | 120mm (usually) | Reduced noise, efficient continuous cooling |

Industrial Panels & Units | 80mm or 120mm | Space available, airflow paths, noise tolerance |

By aligning your choice to these factors, you'll ensure optimal performance, efficiency, and value for your specific use case.

Learn more:

Conclusion

Choosing between an 80mm fan and a 120mm fan involves careful consideration of space limitations, airflow requirements, noise tolerance, and budget constraints. Smaller 80mm micro fans excel in compact spaces where static pressure matters most, while 120mm fans provide quieter, efficient cooling for larger systems. By aligning your selection with these essential factors, you can ensure optimal performance, durability, and cost-effectiveness tailored specifically to your needs.