How to Make a DC Fan Quieter?

This guide explores the most common sources of DC fan noise and offers practical, proven tips to reduce it—ranging from bearing selection and speed control to mounting techniques and maintenance practices.

Why Is Your DC Fan Making Noise?

Excessive noise from DC fans can interfere with product performance and user comfort—particularly in applications like medical devices, consumer electronics, or precision systems. Addressing this issue begins with identifying the root causes. Below are the key sources of DC fan noise and the mechanisms behind them.

Bearing Friction and Degradation

Bearings are central to the smooth motion of a DC cooling fan, but over time they wear due to environmental stress. Elevated temperatures, airborne particles, and moisture all contribute to lubricant breakdown or contamination. As a result, contact between moving parts increases, leading to harsh noises like grinding or buzzing.

Sleeve bearings are particularly prone to lubricant evaporation and particle intrusion. Ball bearings, though more robust, can develop irregular sounds if their tracks degrade or alignment is compromised. These issues are especially noticeable in continuous operation or high-speed setups.

In cases where stability and longevity are critical—such as vertical mounting or harsh-duty cycles—fluid dynamic bearings (FDB) offer improved performance with significantly lower operational noise.

Blade Imbalance and Rotational Irregularity

DC fan blades are engineered for balance, allowing even airflow and vibration-free rotation. However, slight variations in material thickness, wear over time, or physical deformation can shift the mass distribution, making the rotor unstable during spin.

This imbalance pushes the rotational center off-axis, creating periodic forces that result in structural vibration and low-frequency noise. The issue becomes more prominent at higher speeds or when the fan is installed in enclosures that lack damping.

External debris, thermal stress, or mishandling during maintenance may further disrupt the balance. Maintaining consistent blade condition through inspection and proper cleaning is key to preventing related noise.

Dust Accumulation and Airflow Disruption

Dust and airborne debris gradually settle on fan components, altering the symmetry and surface profile of the blades. This leads to uneven airflow, drag increase, and mass imbalance—conditions that all contribute to elevated noise.

Fine particles may also migrate into the bearing housing, leading to increased resistance and premature wear. In environments with static buildup or high humidity, dust may bind together, forming deposits that shift balance and disrupt smooth rotation.

Mitigating this effect involves preventive measures like filtered air intakes and routine maintenance to clear accumulated dust and preserve optimal fan acoustics.

High-Frequency Noise from PWM Control

While PWM is widely used for regulating DC fan speed, it can unintentionally generate audible noise when configured poorly. If the control signal operates at a frequency within the human hearing range (typically 5–20 kHz), it may excite vibrations in magnetically sensitive components like inductors or motor windings.Such vibrations create high-pitched tones, often noticeable in quieter settings. The issue is worsened when there is a lack of filtering or when the signal fluctuates rapidly with abrupt duty cycle changes.To address this, system designers can adopt higher-frequency PWM (above 25 kHz) and ensure compatibility between the dc cooler fan’s internal driver and the external control circuit, minimizing unwanted acoustic side effects.

Tip 1: Choose the Right DC Motor Fan Bearing Type

Pros and Cons in Terms of Noise and Durability

Bearing Type | Noise Level | Lifespan | Cost | Typical Application |

Sleeve | Low (initial) | Short | Low | Budget electronics, basic appliances |

Ball | Moderate | Long | Medium | Industrial devices, telecom systems |

FDB | Very Low | Very Long | High | Medical, aerospace, premium PCs |

The type of bearing used in a DC motor fan plays a key role in determining both its noise characteristics and long-term reliability.

Sleeve Bearings

These bearings are frequently used in cost-sensitive applications due to their simplicity and low initial noise. However, their performance tends to degrade over time, especially in environments with heat or airborne particles. As the internal lubricant evaporates or becomes contaminated, friction increases, which leads to higher noise levels. Sleeve bearings also struggle in vertical orientations because the lubrication does not distribute evenly.

Ball Bearings

Designed for extended use, ball bearings are more durable and can function effectively regardless of mounting position. This makes them a solid choice for industrial or high-load conditions. Despite their longevity, they can introduce more audible mechanical noise, particularly during fan startup or at elevated speeds.

To learn more about how ball bearings enhance fan performance and reliability, check out our detailed guide: What is a Ball Bearing Cooling Fan?

https://www.yccfan.com/articledetail/443.html

Fluid Dynamic Bearings (FDB)

FDB technology utilizes fluid pressure to stabilize the rotor, greatly reducing direct contact between moving components. This results in quieter operation and improved wear resistance. Fans equipped with FDB are often used in noise-critical environments such as medical devices, advanced computing systems, and professional AV equipment where consistent performance and minimal noise are essential.

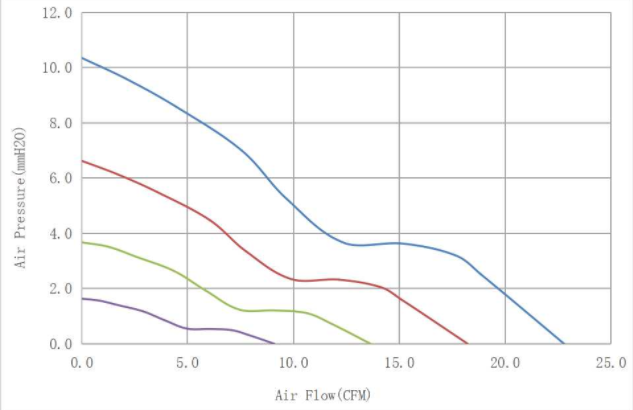

Tip 2:Use PWM Speed Control to Quiet Your DC Cooling Fan

Slower Fan Speed, Quieter Operation

As a DC cooling fan spins faster, the resulting noise increases disproportionately—not only because of the blade movement itself, but also due to intensified airflow turbulence and mechanical vibrations. In scenarios where heat output is moderate or intermittent, forcing the cooling fan to run at full speed can create unnecessary acoustic load.

Reducing the fan’s rotational speed (RPM) during low-demand periods can significantly cut down noise emissions. Even small speed adjustments can make a clear difference in perceived sound, especially in settings where background noise is minimal—like offices, medical equipment, or consumer electronics.

How to Apply PWM for Acoustic Control

Instead of using fixed-voltage control or on-off cycling, Pulse Width Modulation (PWM) provides dynamic speed adjustment by varying the proportion of time the fan receives power in each cycle. This allows precise tuning of fan speed based on system needs.

To implement PWM effectively in a quiet-focused application: Use a 4-pin cooling fan that includes a separate PWM signal wire, enabling direct speed modulation independent of power supply voltage.Set the PWM frequency above 25 kHz, which moves the switching activity outside the audible range for most people. Frequencies below this threshold can cause high-pitched tones, especially in enclosed systems. Establish temperature-based control profiles, so that the fan operates at minimum required speed under light thermal load and gradually increases only when higher cooling is necessary.

By controlling fan speed more intelligently, systems can stay cool without constantly running at maximum output. This not only reduces operating noise, but also lowers mechanical wear, contributing to longer service life and greater energy efficiency.

Tip 3:Optimize DC Cooler Fan Mounting and Vibration Isolation

Reduce Vibration Transmission with Flexible Mounting

Mechanical vibrations are a frequent but often underestimated cause of fan-related noise. When a dc cooler fan is fastened directly to a rigid surface—especially inside metal housings—vibrations from the motor or blade rotation can pass into the surrounding structure, where they resonate and become noticeably louder.

To reduce this effect, it's advisable to install flexible mounting elements such as rubber grommets or silicone bushings between the dc cooler fan and its mounting surface. These materials act as buffers that absorb and dampen vibrational energy before it travels into the enclosure.

This method is particularly useful in systems with lightweight or thin metal walls, which are prone to amplifying even minor vibrations.

Prevent Noise Amplification Through Direct Contact

When the fan frame is in direct contact with a bare metal surface, even small vibrations can turn the enclosure into a resonating body, intensifying background hum or rattling. To mitigate this, apply thin isolating materials—like foam pads, rubber strips, or acoustic spacers—at the contact points.

These barriers act as a break in the mechanical path, limiting the transfer of vibrational energy into the chassis. This simple adjustment can make a noticeable difference in reducing low-frequency structural noise, without compromising the fan’s stability or airflow performance.

Discover more:

https://www.yccfan.com/articledetail/520.html

https://www.yccfan.com/articledetail/518.html

https://www.yccfan.com/articledetail/510.html

Conclusion

Reducing DC cooling fan noise doesn’t require sacrificing performance. By identifying the specific source—whether it's bearing wear, imbalance, dust buildup, or PWM-related hum—you can apply targeted solutions that improve acoustics and extend the life of your system.