Industrial Cooling Fans: Overview, Uses And Benefits

Efficient thermal management is essential in today’s high-performance industrial environments—where electronic systems, automation equipment, and power devices often operate under intense workloads and in confined spaces. Without proper cooling, even the most advanced machinery can suffer from overheating, reduced efficiency, or premature failure.

This article is a comprehensive guide to industrial cooling fans, covering what they are, how they work, the different types available, their benefits, typical use cases across industries, and how to choose the right fan for your application.

What Are Industrial Cooling Fans ?

Industrial cooling fans are specialized air-moving devices engineered to regulate thermal conditions in demanding operational environments. Their core function is to generate directed airflow that actively removes excess heat from components, enclosures, or workspaces—helping to maintain a stable thermal balance and prevent heat-related failures. Unlike passive cooling methods that rely solely on natural air movement, these fans deliver consistent and responsive thermal control, essential for equipment that operates continuously or under heavy load.

Compared to consumer fans, which are primarily designed for human comfort in relatively stable and clean settings, industrial cooling fans are built for endurance and reliability in rugged conditions. They feature heavy-duty materials, heat-tolerant construction, and designs that withstand environmental stressors such as dust, humidity, oil vapor, and vibration. Additionally, many industrial models come with smart features like speed regulation, thermal shutdown protection, and ingress protection (IP) ratings—making them suitable for high-risk or mission-critical installations. Their extended service life and reduced maintenance demands also contribute to long-term cost efficiency.

In modern manufacturing and industrial systems, cooling fans are more than just accessories—they’re integral to system stability and equipment longevity. As machines and electronics become more compact yet more power-hungry, the risk of localized heat buildup increases. Industrial fans help mitigate this by providing directed airflow precisely where it’s needed—whether it's across densely packed PCBs, inside sealed control panels, or over the casings of power modules. Their use spans automation systems, renewable energy infrastructure, telecommunications, medical devices, and more, making them a key enabler of operational continuity and energy efficiency in today’s industrial landscape.

Types of Industrial Cooling Fans

Type | Airflow & Pressure | Key Features | Typical Applications |

Axial Fans | High airflow, low static pressure | Simple structure, compact size | Electrical enclosures, server racks, power supplies |

Centrifugal Fans | Lower airflow, higher static pressure | Suitable for ductwork, stable pressure over distance | Air filtration systems, HVAC, industrial dryers |

Blowers | Focused, high-speed airflow | Directional output, space-efficient | Localized cooling, 3D printers, sensors |

EC (Electronically Commutated) Fans | Adjustable airflow with high efficiency | Variable speed control, energy-saving, low noise | Energy-efficient systems, telecom, automation |

How Do Industrial Cooling Fans Work?

Industrial cooling fans operate by generating controlled airflow to remove excess heat from components, enclosures, or systems that generate thermal loads. Their working principle relies on forced convection, where moving air accelerates the transfer of heat from hot surfaces to the surrounding environment—far more effectively than passive cooling.

At the heart of each fan is an electric motor connected to a set of impellers or blades, designed to move air either along the motor’s axis (in axial fans) or perpendicular to it (in centrifugal fans). As these blades spin, they create a pressure differential that draws in cooler ambient air and pushes out warmer air, maintaining a consistent thermal balance.

The fan’s internal structure includes ball or sleeve bearings, which support smooth, low-friction rotation over extended periods. Surrounding this mechanism is the fan housing, typically made from industrial-grade plastic, aluminum, or coated metal. This housing helps direct airflow and shields internal components from dust, moisture, vibration, and other harsh environmental factors common in industrial settings.

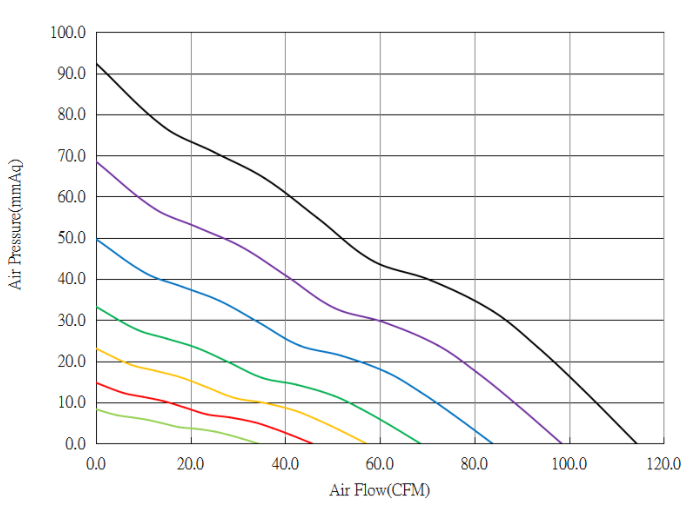

Two key performance metrics define how effectively a fan works:

CFM (Cubic Feet per Minute) measures how much air the fan moves per minute—higher values mean greater cooling capacity.

Static pressure reflects the fan’s ability to push air through resistance-heavy spaces like heat sinks, filters, or dense enclosures.

Modern industrial fans often go beyond basic operation by incorporating intelligent control systems. For example, PWM (Pulse Width Modulation) allows for real-time speed adjustments, reducing noise and conserving energy during low thermal loads. EC motors (Electronically Commutated) offer even greater efficiency and quieter operation, combining AC power input with DC motor performance. Temperature sensors can also be integrated, enabling fans to turn on or adjust speed only when needed—minimizing unnecessary power consumption.

Together, these components and technologies create a cooling system that is not only reliable and efficient but also adaptive to varying operational demands. From control cabinets and power supplies to telecom equipment and automation lines, industrial cooling fans serve as a core component in thermal management systems, ensuring long-term equipment stability and performance.

What Are the Benefits of Industrial Cooling Fans?

Industrial cooling fans do far more than circulate air—they are a foundational element in preserving the operational stability and efficiency of critical systems. Their foremost role is to maintain thermal balance, ensuring that electrical components, machinery, and sensitive electronics remain within safe temperature thresholds. By actively managing heat, these fans help prevent thermal stress that can otherwise lead to hardware failure, performance throttling, or unexpected system shutdowns.

Stable temperatures also enhance overall energy efficiency. Equipment running at optimal heat levels performs more consistently and consumes less power, translating to lower energy bills and extended system lifespan. This improved thermal regulation reduces the likelihood of component fatigue and minimizes unscheduled maintenance—particularly vital for industries where continuous operation is non-negotiable, such as data centers, automated factories, and power systems.

Durability is another key strength of industrial cooling fans. Built to function in harsh and unpredictable environments, they are designed to resist dust, moisture, corrosive elements, and constant vibration. With rugged housings, high-grade bearings, and protective coatings, these fans are engineered to deliver long-term reliability, even under extreme operating conditions.

Additionally, today’s industrial fans are optimized for low-noise, low-vibration performance, making them suitable for environments where sound levels are a concern, such as laboratories, medical equipment enclosures, or control rooms. Their low-maintenance architecture reduces the frequency of service intervals, helping businesses cut down on operational downtime and service costs over the product’s lifecycle.

Equally important, many industrial cooling fans are certified to international safety and compliance standards such as CE, UL, and RoHS. These certifications confirm the product’s adherence to strict quality, electrical safety, and environmental guidelines—making them ideal for integration into globally distributed systems or OEM product lines that must meet regulatory requirements across regions.

In short, industrial cooling fans not only protect hardware—they also support energy savings, uptime continuity, long-term durability, and global compliance, making them indispensable to modern industrial design.

Where Are Industrial Cooling Fans Used?

Industrial cooling fans play a pivotal role across a wide range of industries where managing heat is essential to maintaining system stability and operational continuity. One of the most prevalent use cases is within electrical and electronic enclosures, where densely packed circuit boards and power components generate significant heat in confined spaces. Fans ensure proper ventilation, allowing these systems to function reliably without thermal interruption.

In the telecom sector, fans are vital to maintaining temperature control in base stations, routers, and network cabinets—especially as hardware becomes smaller and more powerful. Without adequate airflow, even minor heat buildup can lead to signal degradation, reduced efficiency, or premature failure.

Industrial automation systems and robotic platforms also require dependable cooling to protect motion controllers, drives, and sensors. These systems often operate continuously and under high-speed conditions, where a sudden temperature spike could disrupt precision or halt operations altogether.

In medical and laboratory applications, cooling solutions are applied in equipment such as diagnostic analyzers, imaging systems, and high-sensitivity instruments. Here, fans must offer not only thermal performance but also quiet, low-vibration operation to avoid interfering with measurements or patient comfort.

When it comes to power electronics—such as inverters, converters, and high-capacity power supplies—cooling fans are indispensable. These devices produce concentrated heat during operation, and without proper cooling, internal circuits can degrade or fail. Industrial fans help maintain optimal performance and energy efficiency in these high-load environments.

In the renewable energy space, including solar inverters, energy storage systems, and EV charging stations, fans are integrated to support consistent output even under fluctuating environmental conditions. Outdoor exposure, rapid charge-discharge cycles, and load variability all demand robust and responsive cooling.

Lastly, HVAC systems and factory-wide ventilation setups rely on larger industrial fans to regulate building temperatures, improve air quality, and manage airborne particles. In high-output areas like production lines, these fans ensure worker comfort and protect machinery from excessive ambient heat.

Choosing the Right Industrial Cooling Fan

Selecting the appropriate industrial cooling fan goes beyond simply matching size and airflow—it's about balancing thermal performance, environmental conditions, and integration requirements.

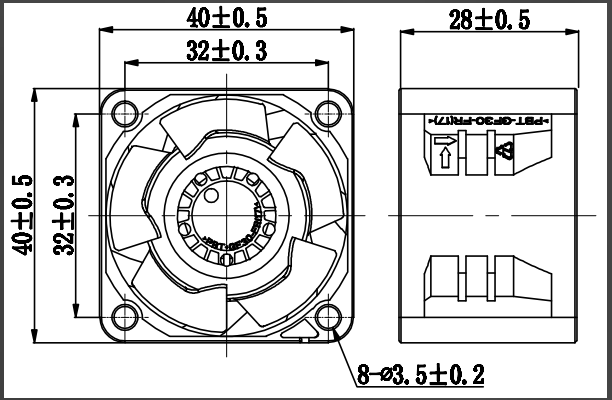

Start with dimensional and mounting constraints. Whether the fan is installed in a control cabinet, rack, or embedded system, it must align precisely with the available space and mounting interface. Compatibility here ensures easy installation and long-term mechanical stability.

Next, evaluate the cooling performance requirements—specifically, the airflow (CFM) needed to move sufficient air volume, and static pressure if airflow must overcome resistance from filters, vents, or tight channels. High CFM is ideal for free-flowing environments, while elevated static pressure is crucial in obstructed or compact layouts.

Electrical compatibility is another critical factor. Industrial fans are offered in various voltages—12V, 24V, 48V DC, and 110V or 220V AC—so it's important to align with the system’s power architecture for optimal safety and efficiency.

In environments where noise matters—like medical, telecom, or office-adjacent installations—acoustic performance should be a deciding factor. Models equipped with PWM control or speed-regulation functions can maintain low noise while adapting fan speed to thermal demand.

For industrial settings exposed to moisture, dust, or particulates, be sure to check the fan’s IP (Ingress Protection) rating. A higher IP rating ensures protection from environmental contaminants and supports long-term reliability even under harsh conditions.

Finally, for projects with unique thermal demands or spatial constraints, OEM or customized fan solutions can offer a better fit. Manufacturers often provide tailored designs—ranging from specific blade geometries to programmable control features—that align perfectly with specialized applications.

Read more:

https://www.yccfan.com/articledetail/520.html(What is the Difference Between Industrial Cooling Fan and Commercial Fan?)

https://www.yccfan.com/articledetail/519.html(The Future of Cooling Fan Manufacturers in the Age of Sustainable Development)

https://www.yccfan.com/articledetail/514.html(How to Pick the Right Industrial Fan Factory?)

Conclusion

Industrial cooling fans are far more than peripheral components—they are critical to maintaining safe, efficient, and uninterrupted operations in a wide variety of sectors. From preventing heat-related failures to enabling intelligent, energy-efficient systems, these fans are indispensable for modern industrial design. By understanding their functions, types, and selection criteria, businesses can make informed decisions that enhance system reliability and extend equipment lifespan.