How Many CFM Is Good for an Industrial Cooling Fan?

This guide explains what CFM really means, how much airflow is considered “good” in different industrial applications, and how to choose the right fan based on real operating conditions rather than headline numbers alone.

What CFM Means for an Industrial Cooling Fan

CFM (cubic feet per minute) tells you how much air an industrial cooling fan can move each minute. As CFM increases, airflow generally becomes more noticeable and effective—helping refresh stagnant air and move heat away from equipment surfaces and work zones.

In industrial settings, heat loads come from many directions: machinery, motors, lighting, people, and process equipment. If CFM is undersized, air won’t reach the hottest areas and temperatures can build up; if it’s oversized or poorly applied, you may spend more energy without getting more uniform cooling. The goal is the“right-fit”CFM—enough to minimize hotspots, improve comfort, and reduce the risk of heat-related derating or avoidable operating costs.

Choosing Industrial Cooling Fan CFM by Application

Typical CFM Ranges

Application Area | Typical Fan Use | Recommended CFM Range |

Workshops / shipping docks | targeted airflow | 3,500–8,500 CFM |

General warehouse | large area circulation | 10,000–33,000+ CFM |

Factory / gymnasium | continuous heat + large space | 20,000–44,000+ CFM |

Very large/high ceiling | multiple fans/system design | 40,000+ CFM |

What qualifies as a“good”CFM really depends on the job your industrial cooling fan is doing—air circulation (comfort and destratification) or ventilation/exhaust (moving heat out and refreshing air). In large, open areas where the goal is broad air movement, HVLS fans tend to work well because they move a large air mass gently across the space rather than trying to force air through restrictions. But when airflow has to pass through ducts, filters, louvers, or tight internal paths, CFM alone can be misleading—static pressure becomes a key part of whether the air actually reaches where it needs to go.

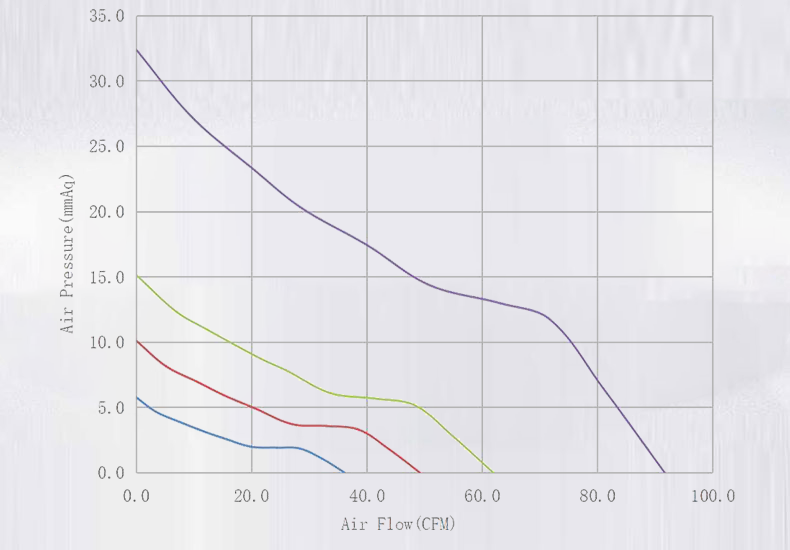

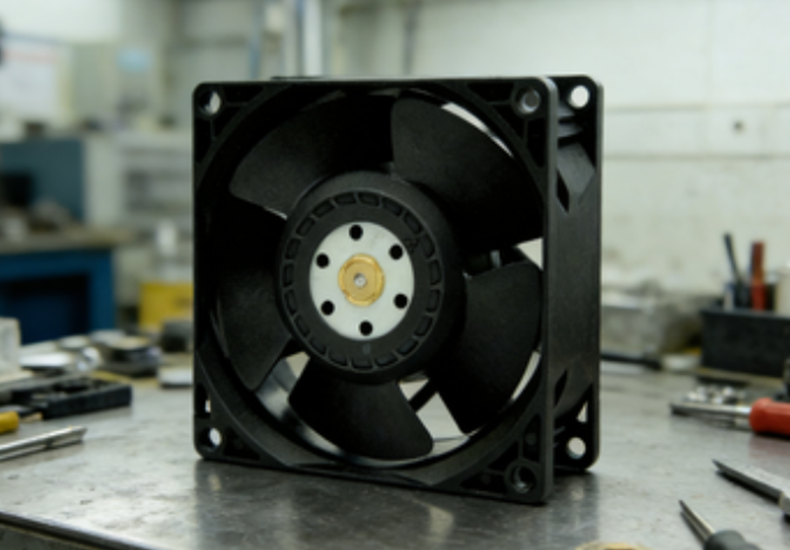

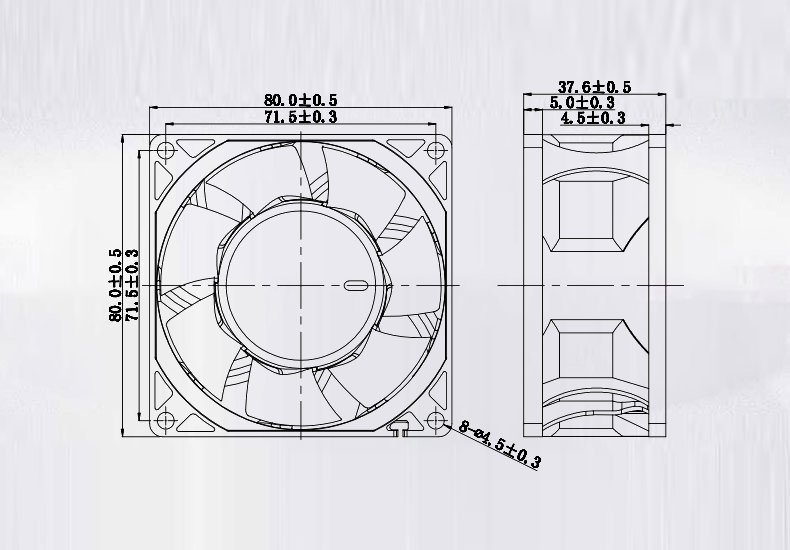

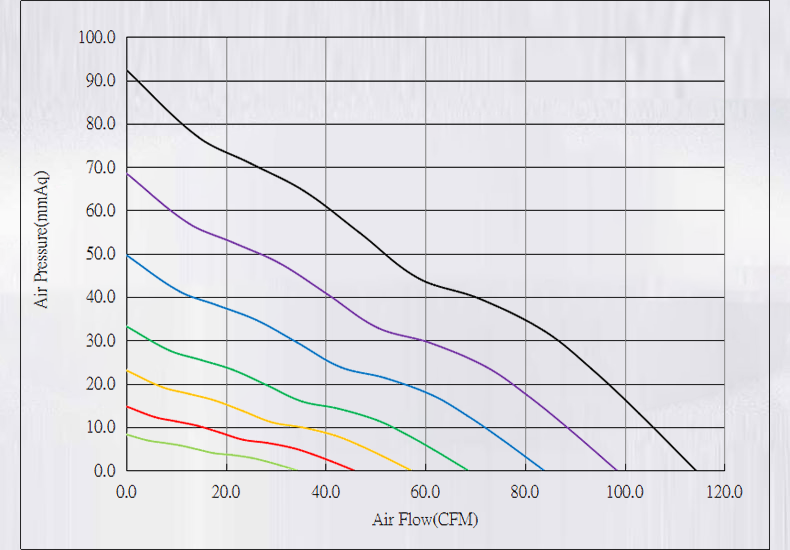

That’s why, in real selection work, engineers evaluate airflow and static pressure together, not CFM in isolation. For instance, one published example from YCCFAN is the DC8038, which lists up to 62.62 CFM along with 32.38 mmH₂O of static pressure. Pairing these two numbers helps indicate that the fan can keep air moving even when resistance is higher—making it a more practical fit for ventilation or heat-exhaust paths. For circulation-focused cooling, the priority shifts toward coverage and overall air mixing, rather than peak airflow at a single measurement point.

Key Factors That Determine the Right CFM for a Cooling Fan Industrial

1.Space Volume (Most Important)

CFM should be based on the total air volume you need to move, not just the floor footprint. Two spaces with the same square footage can require very different airflow if one has a higher ceiling or more enclosed volume. In practice, sizing from volume is the simplest way to avoid “not enough air” in tall areas—or paying for more airflow than a smaller space can actually use.

2.Ceiling Height & Stratification

Tall buildings often develop layered temperatures, with hot air collecting above the occupied zone. For an industrial cooling fan to feel effective at work level, airflow has to mix the space and bring that trapped heat down into circulation. That’s why a CFM number that feels strong in a low-ceiling workshop may feel underwhelming in a high-bay facility.

3.Heat Load & Equipment Density

Airflow demand rises with process heat. Dense equipment layouts—motors, compressors, ovens, weld cells, and continuous-duty lines—can create concentrated hot areas that need higher CFM and/or higher air-change targets. On the floor, an undersized setup usually shows up as stubborn hotspots, frequent thermal warnings, or derating during peak production.

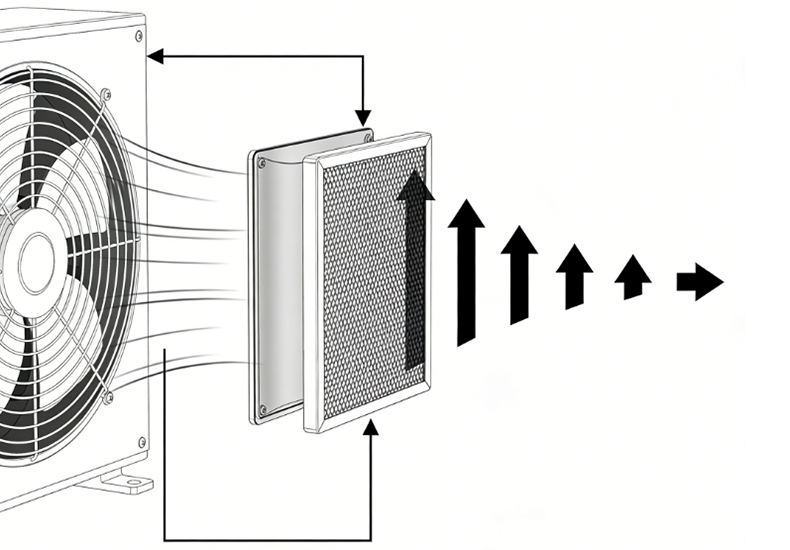

4.Airflow Resistance (Filters, Ducts, Louvers)

Once air has to move through filters, ducts, louvers, or narrow passages, static pressure becomes a deciding factor alongside CFM. A cooling fan industrial rated high in free air can lose a large portion of its airflow when resistance is added, so engineers often compare airflow–pressure performance instead of looking at CFM alone. For example, YCCFAN lists both airflow and static pressure on models such as the DC8038 (up to 62.62 CFM and 32.38 mmH₂O), which helps indicate whether the fan can still “push” air in higher-resistance paths rather than only in open-air conditions.

How to Calculate CFM for Cooling Fan

One practical way to size CFM for industrial cooling is the ACH approach: CFM = (Room Volume in ft³ × Target ACH) ÷ 60. As a rough field guide, lighter ventilation is often around 4–6 ACH, general industrial areas commonly fall in 6–10 ACH, and high-heat processes may push to 10+ ACH. If you need a faster estimate for large spaces with 18–30 ft ceilings, a starting point for comfort airflow is about 2–3 CFM per square foot, then fine-tune based on heat sources, space layout, and any restrictions like ducts, filters, or louvers.

Choosing Cooling Fan Type Matters as Much as CFM

HVLS Fans (Large Spaces)

In large, open buildings, the main objective is usually whole-area air movement—mixing the space to reduce hot layers near the ceiling and improve comfort on the floor. HVLS cooling fans are well suited for this because they prioritize coverage and gentle, wide circulation rather than forcing air through restrictions. CFM still matters, but it works best when considered alongside ceiling height, layout, and how many zones you need to cover.

High-Velocity Fans (Workstations / Docks)

If the goal is targeted cooling—for a workstation, a dock door, or a hot piece of equipment—high-velocity fans are often more effective than wide-area circulation. In tighter setups where air has to pass through guards, filters, ducting, or enclosures, CFM alone doesn’t tell the full story; static pressure heavily influences how much air actually gets through. This is why engineers often rely on airflow–pressure data when selecting DC fans. For example, YCCFAN publishes both airflow and static pressure for models such as the DC8038, which helps estimate real performance in higher-resistance paths rather than only in free air.

Don’t Oversize

More airflow on paper doesn’t automatically mean better results. Oversizing can raise energy use, create drafts, and still leave uneven cooling if airflow is poorly directed. A more reliable approach is to choose the right fan type first—coverage-focused for open spaces, pressure-capable for restricted paths—then size CFM around the actual heat load and airflow route.

Conclusion

There’s no single CFM value that works for every industrial environment. A well-sized industrial cooling fan balances airflow, static pressure, space volume, heat load, and fan type.

Read more:

https://www.yccfan.com/articledetail/what-is-the-role-of-dc-blower-fans-in-office-equipment.html

FAQ

1) Is 2000 CFM a lot for a fan?

It depends on the industrial fan type and the space. 2000 CFM is high for many small ventilation fans, but it can be modest for large industrial fans or big open areas.

2) What CFM is good for an industrial cooling fan?

Most industrial cooling fan needs fall between ~3,500 and 40,000+ CFM. The right number depends on room volume, heat load, and airflow resistance.

3) How do I choose CFM for a warehouse vs a workshop?

Warehouses usually need higher total airflow and wider coverage. Workshops often need lower CFM but more targeted airflow at hot zones or workstations.

4) Does higher CFM always cool better?

Not always. If airflow is blocked by filters/ducts or the industrial cooling fan lacks static pressure, real airflow can drop and cooling may still be uneven.

5) How many industrial cooling fans do I need instead of one high-CFM fan?

Use multiple fans when coverage is the issue. Several properly placed fans often deliver more uniform cooling than one oversized fan, especially in long or partitioned spaces.