What is a Blower Fan Used For?

Understanding what a blower fan is used for helps engineers and buyers choose the right solution for ducted, enclosed, or resistance-heavy applications where ordinary fans fall short.

What Is a Blower Fan?

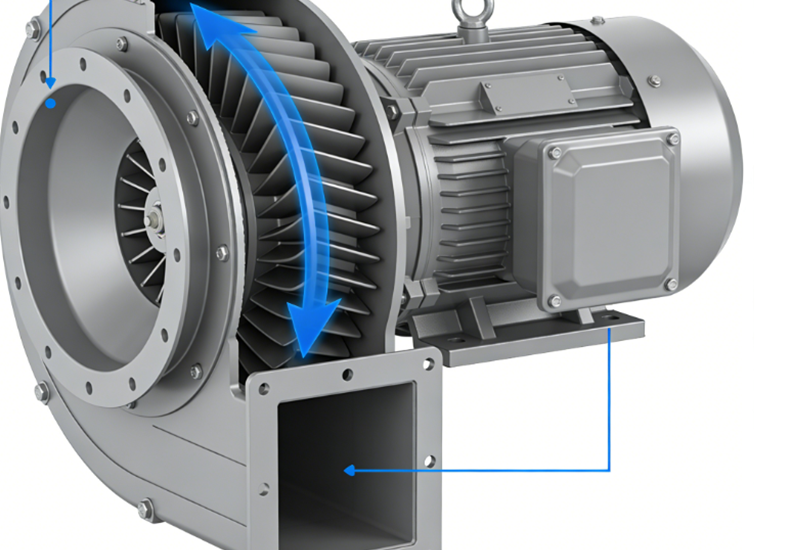

A blower fan is made to produce a fast, directed airstream with moderate-to-high pressure. With its centrifugal design, it pulls air in and pushes it out through a defined outlet, which makes the airflow easier to steer—especially in compact devices, enclosed housings, or ducted layouts where you need controlled airflow rather than general circulation.

In real-world use, its advantage becomes clear when the airflow path isn’t“open.”Once air has to pass through grills, filters, ducts, or narrow channels—where many standard fans quickly lose flow—a blower fan is more likely to maintain effective airflow and deliver cooling or ventilation right where it’s needed.

Application Overview Table

Application | What the Blower Fan Does | Why It’s Used |

HVAC duct systems | Pushes conditioned air through ducts | Works well under resistance |

Industrial process air | Supplies combustion/aeration air | Stable, directed airflow |

Drying/cleaning lines | Powers air knives / dry-off airflow | Focused high-velocity output |

Dust/fume extraction | Pulls air through ducts + filters | Maintains airflow in filtered systems |

Inflatables | Provides constant air supply | Keeps structure inflated |

Electronics/cabinets | Targets hotspots in compact layouts | Better airflow control |

Common Uses of a Industrial Blower Fan

1.HVAC Systems (Ducted Air Delivery)

In HVAC equipment, industrial blower fans are typically used whenever air must be pushed through ductwork rather than allowed to circulate freely in open space. Ducts, bends, and filters all add resistance, and a blower fan is better suited to maintain stable airflow as air moves through furnaces and air-handling units.

From field experience, systems with defined air paths often struggle to deliver air effectively when standard fans are used, even if their free-air ratings look high. This is why HVAC designs rely on blowers when airflow must follow a controlled route.

2.Industrial Processes (Process Air & Equipment Cooling)

Many industrial applications require controlled and repeatable airflow, not just general ventilation. Blower fans are commonly used to supply combustion air for furnaces, support aeration in wastewater treatment, or provide directed cooling to machinery with localized heat buildup.

At the equipment level, suppliers such as YCCFAN focus on DC blower fan solutions that balance airflow and pressure, making integration easier in compact industrial systems. In practice, fans selected with both airflow and pressure in mind tend to perform more reliably than those chosen based on airflow alone.

3.Drying and Cleaning (Air Knife / Dry-Off)

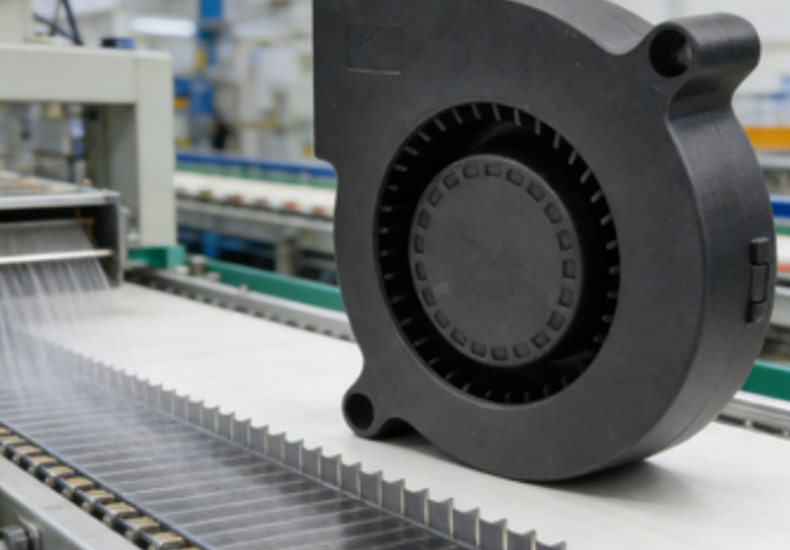

Drying and cleaning processes often depend on focused, pressurized airflow rather than large volumes of free air. In production environments, blower-driven air is used to remove debris, dry products on conveyor lines, or feed air knives in packaging and surface-treatment systems.

From real-world use, maintaining steady pressure is key—without it, airflow can become uneven, leading to inconsistent drying or cleaning results across the working width.

4.Fume and Dust Extraction (Workshops & Manufacturing)

Fume and dust extraction systems rely on blower fans to pull contaminated air through ducting and filtration stages. As duct runs become longer or filters gradually load with debris, system resistance increases.

In these conditions, blower fans are more capable of maintaining extraction performance over time, helping workshops and manufacturing facilities keep air quality stable instead of seeing airflow drop off after extended operation.

5.Inflatables (Continuous Air Supply)

Inflatables such as bounce houses or advertising structures depend on a continuous air supply to maintain their shape. Blower fans are well suited for this role because they can operate for long periods while delivering consistent airflow.

In these applications, durability and steady output are typically more important than achieving ultra-low noise levels.

6.Electronics Cooling (Computers & Industrial Cabinets)

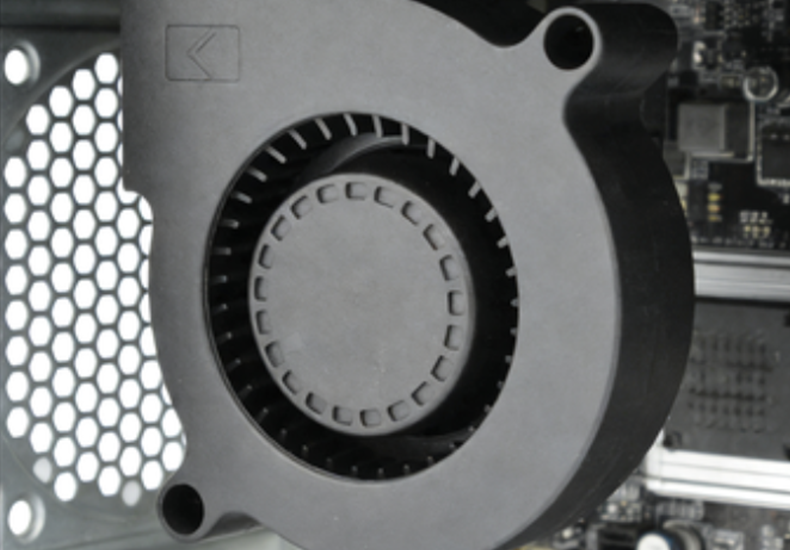

In compact electronics and enclosed cabinets, airflow must be guided, not dispersed. Blower fans are used to direct air across heat sinks, power modules, and other hotspots within tight internal layouts.

From practical design experience, DC blower fans—such as those commonly used in YCCFAN’s equipment-cooling solutions—are often selected because they support controlled airflow paths and reliable continuous operation in space-constrained environments.

When a DC Blower Fan Is the Right Choice

1.When a DC Blower Fan Makes More Sense

A dc blower fan is usually the better option when the airflow route has built-in resistance—ducts, filters, grills, louvers, or tight internal passages that naturally slow air down. In these cases, pressure capability is what keeps airflow from collapsing once the fan is installed. Blowers are also a strong fit when air needs to be delivered to a specific spot, such as cooling a hotspot, drying a surface, or pulling fumes from a defined zone. The priority here is reliable, “in-system” airflow—not just a high CFM figure measured in open air.

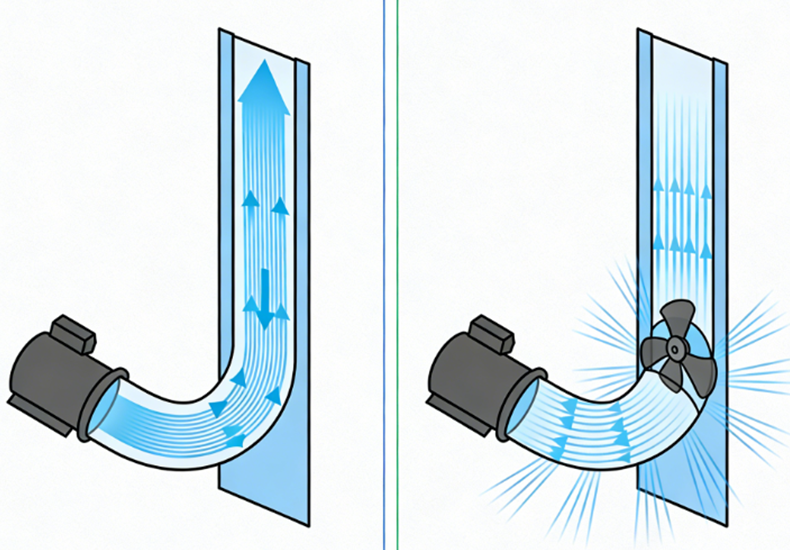

2.When an Axial Fan Is the Better Fit

An axial fan makes more sense when the airflow path is open and low-resistance, with little to no ducting, filtration, or narrow channels. It’s well suited for general ventilation and wide-area circulation, especially when you want to move air across a larger space for comfort. In these setups, static pressure isn’t usually the limiting factor, so an axial fan often provides a clean, efficient solution without unnecessary complexity.

Read more:

https://www.yccfan.com/articledetail/how-many-cfm-is-good-for-an-industrial-cooling-fan.html

Conclusion

A blower fan is the right choice when airflow needs to be directed, controlled, and maintained under resistance.

FAQ

1.What is a blower fan used for in HVAC?

To push heated or cooled air through ductwork where airflow resistance is present.

2.Is a blower fan better than an axial fan?

Only when pressure or directed airflow is needed; axial fans are better for open, low-resistance ventilation.

3.Can a blower fan be used for drying or air knives?

Yes. Blower fans provide the focused, pressurized airflow required for effective drying and air knife systems.

4.Why do extraction systems use blower fans?

Because they can maintain airflow through ducts and filters as resistance increases.

5.What should I check besides CFM when choosing a blower fan?

Static pressure, airflow direction, noise level, and whether the fan matches the actual airflow path.