Why Are Blower Fans So Loud?

If your blower fan sounds louder than it used to, it’s usually not “just noise”—it’s a clue that airflow, mechanics, or control conditions have changed. Because blowers move air with higher velocity and pressure, they’re naturally more sensitive to restrictions, imbalance, and wear. The good news is that most noise issues can be traced to a few common causes and often improved with straightforward checks and maintenance.

How Blower Fan Design Contributes to Noise

1.High-Velocity, High-Pressure Airflow

Blower fans are built to push air forcefully, not just move it around. That design naturally creates higher airspeed at the outlet, and with higher speed comes more turbulence. In everyday use, this turbulence is what people hear as rushing or whistling—most noticeably when the outlet opening, duct size, or grille area doesn’t give the airflow enough room to expand smoothly.

2.The Pressure–Noise Balance in Real Installations

The same pressure capability that lets a blower fan perform well in tight or ducted systems can also make noise more apparent if the system isn’t well matched. In the field, excessive noise is often traced back to airflow paths that are too restrictive—sharp turns, loaded filters, or undersized inlets increase resistance and force the fan to run under higher stress, which raises both air noise and vibration. This is why experienced engineers don’t look at airflow alone; they evaluate airflow together with static pressure. Manufacturers such as YCCFAN publish both values for their DC blower fans, helping designers select a model that suits the real resistance of the system and avoid unnecessary noise caused by overspecifying the fan.

Common Industrial Blower Fan Noises & What They Mean

Noise Type vs. Likely Cause

Noise Type | Likely Cause | What It Usually Indicates |

Rattling | Loose screws / debris | Mechanical looseness |

Screeching / Squealing | Worn bearings | Motor or bearing wear |

Humming / Buzzing | Bad capacitor | Electrical fault |

Whistling | Clogged filter / restricted duct | Airflow restriction |

Loud rushing air | High air velocity | Duct or outlet mismatch |

Common Reasons Industrial Blower Fans Become Loud Over Time

1.Airflow-Related Noise (Most Common)

A industrial blower fan often gets louder when the airflow path starts to“tighten up.”Clogged filters, narrow ducting, or a partially blocked inlet force the same air through a smaller opening, which raises airspeed and turbulence—usually heard as a sharper rush or whistle. In real service work, noise frequently drops as soon as airflow is restored (cleaning the intake, replacing filters, or removing a restrictive grille) without changing the fan itself. This matches YCCFAN’s selection guidance as well: real airflow depends heavily on how much resistance the downstream path adds.

2.Component Wear (Bearings & Motor Aging)

With long run time—especially in continuous-duty equipment—mechanical wear gradually becomes a factor. Bearings are a common source: the sound shifts from normal airflow noise to squeal, scrape, or a rough growl, and it often gets worse as speed increases. A quick practical check is this: if the noise remains after you’ve cleared restrictions and improved airflow, wear is usually the more likely cause.

3.Loose or Unbalanced Parts

Rattling or strong vibration typically points to hardware issues—fasteners loosening, mounts softening, or the blower wheel drifting slightly out of balance. Even a small imbalance can transfer vibration into the housing and make the fan sound much louder than expected. This is why balancing matters in production: YCCFAN notes using balancing equipment and testing for fans and blowers, since imbalance is a direct driver of vibration and noise.

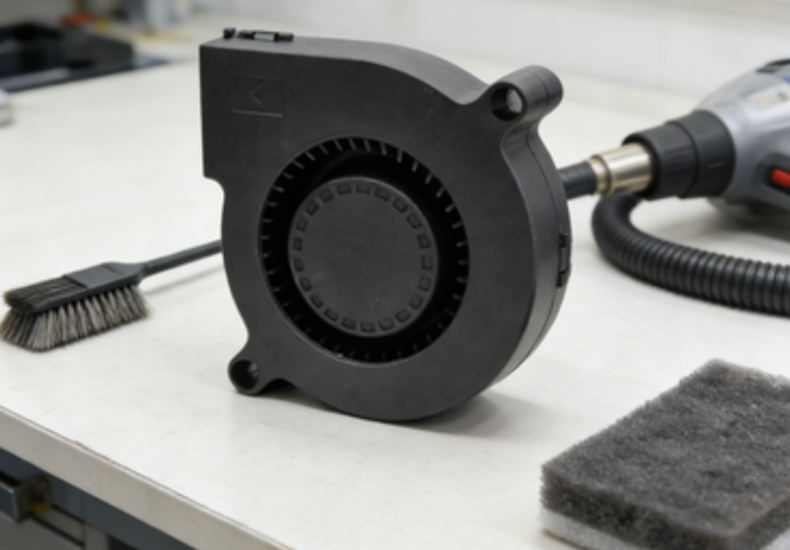

4.Dirt and Debris Accumulation

Dust doesn’t only reduce airflow—it can also disrupt smooth rotation. When buildup collects unevenly on the blower wheel, vibration increases and the fan can start sounding“rough,”even if the motor is still healthy. In maintenance practice, cleaning the wheel is often one of the fastest fixes when noise creeps up gradually over weeks or months.

5.Electrical Issues (Capacitor or Drive Problems)

If the sound is more hum or buzz than airflow, the issue is often electrical. In AC systems, a weakening capacitor is a common trigger; in DC systems, unstable input power or control signals can cause speed hunting and unusual noise. Since many YCCFAN industrial DC blower models support functions like PWM/FG/RD, it’s worth checking wiring, signal stability, and control settings—especially if the noise appears alongside irregular speed behavior.

How Regular Maintenance Reduces DC Blower Fan Noise

1.Cleaning and Filter Replacement

Keeping airflow “clean and open” is often the fastest way to reduce noise. When filters load up, inlets get partially blocked, or dust collects on the wheel, resistance increases and airflow becomes more turbulent—so the dc blower fan sounds louder even if nothing is actually broken. In many day-to-day cases, a simple routine of timely filter changes plus wheel and housing cleaning brings the sound level back down without touching the motor.

2.Mechanical Inspection

A short inspection can stop small mechanical issues from turning into constant noise. Over time, bearings wear, mounts soften, and fasteners can loosen, which is when vibration starts to travel through the housing and become audible. Spotting early signs—slight play, light rattling, or uneven rotation—usually means the fix is minor, and it helps avoid bigger problems like severe noise, performance drop, or unplanned downtime.

Read more:

https://www.yccfan.com/articledetail/what-is-a-blower-fan-used-for.html

https://www.yccfan.com/articledetail/how-many-cfm-is-good-for-an-industrial-cooling-fan.html

Conclusion

Blower fan noise typically comes down to two things: how the air is being forced through the system, and how healthy the fan components are over time. When ducts, filters, or inlets add resistance, airflow noise rises; when bearings wear, parts loosen, or debris builds up, vibration and mechanical sounds take over.

FAQ

1.Why is my blower fan suddenly louder than before?

Usually airflow is restricted (dirty filter/blocked inlet) or something has loosened, causing turbulence or vibration to spike.

2.Is a loud blower fan dangerous?

It can be—grinding, screeching, or electrical buzzing may indicate bearing failure or electrical issues that could lead to overheating.

3.How do I quiet a blower fan without replacing it?

Start with filter replacement and cleaning the blower wheel, then check mounts/fasteners to eliminate vibration.

4.What does a rattling noise in a blower fan mean?

Most often it’s loose hardware, debris in the housing, or an unbalanced wheel causing vibration.

5.Does higher static pressure make a blower fan louder?

It can. Higher pressure often means higher airspeed and turbulence, especially if the airflow path is restrictive or poorly matched.